Magnetics locks, or maglocks, are a popular choice in many security systems. For these locks, an electromagnet is mounted on the door frame, and a metal plate is attached to the door. When powered, the electromagnet creates a strong magnetic force that holds the aligned metal plate, keeping the door securely closed.

While this might seem like a straightforward security solution, the reliance on electromagnetic force brings with it several notable challenges. These challenges can significantly impact the security of the building and overall effectiveness of maglocks in various settings.

Challenges of Maglocks

Power Dependency

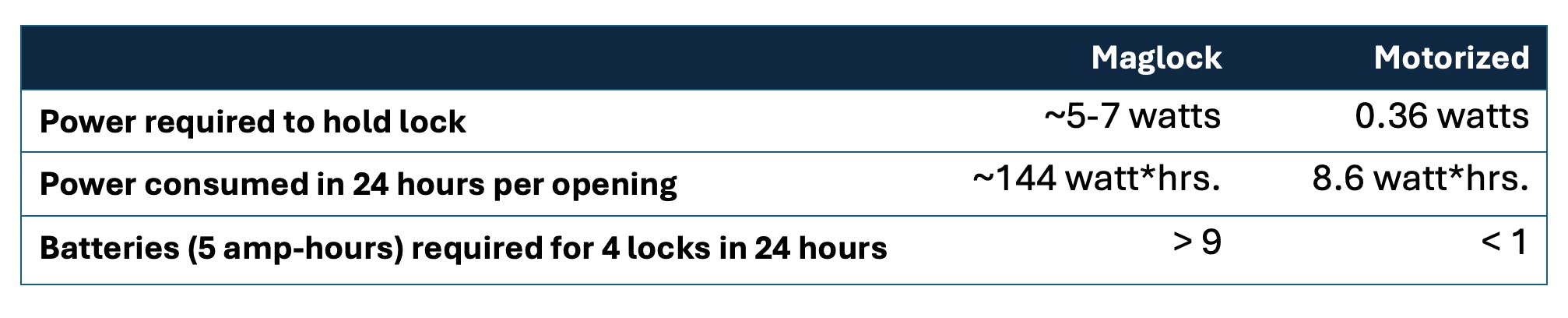

Maglocks rely on a continuous electrical supply (around 0.5A when the voltage supply is 12VDC) to maintain their locked state. This reliance on power makes them susceptible to security vulnerabilities during power outages or electrical failures. If the power supply is disrupted, whether due to a blackout or malfunction, the maglock will automatically disengage, potentially compromising the security of the premises.

Backup Power

If maglocks are the sole means of securing your doors, battery backups in power supply boxes become essential. However, batteries require maintenance and periodic replacement to ensure they maintain charge. This adds cost and requires schedule tracking.

Furthermore, battery backups are typically designed to provide power for short durations, such as a few hours to a day. Extended power outages can deplete the batteries, leading to the disengagement of the maglocks and leaving the premises unprotected. If a motorized latch retraction system experiences a failure, the door remains securely locked even without power.

Installation and Degradation Challenges

A common issue installers face is "sticky” maglocks where residual voltage requires users to forcibly tug on the door to open it. If the locks become stuck and can’t disengage properly, you’ll need to break the door to resolve the problem which can be costly.

Installing maglocks requires precise alignment and careful integration with door frames and strike plates. Improper installation can lead to misalignment issues, causing the lock to fail to release properly or a distance that causes the magnetic field to be significantly weaker.

Additionally, because there is a constant supply of power needed for maglocks, this can lead to wear and tear such as coating degradation.

Alternative to Maglocks

Electrification of door hardware has several advantages over maglocks. Motorized electrification has become the preferred solution for motorized latch retraction and lever control due to its enhanced energy efficiency and extended life cycle.

Reduced Power Consumption

Motorized latch retraction systems consume significantly less electricity over time compared to maglocks, which continually draw power even when not actively engaged in locking or unlocking doors. This reduced power consumption not only contributes to lower operational costs but contributes to the longevity and reliability of the overall security system, as there is less wear and tear on components and reduced risk of electrical failures over time.

Reliability During Power Outages

Unlike maglocks, which require a continuous power supply to remain locked, motorized latch retraction can be relied upon during power disruptions. Motorized latch retraction systems offer peace of mind by removing this critical dependency. Their design ensures that the locking mechanism remains engaged regardless of power conditions, providing consistent and reliable security.

Even with battery backups, maglocks are not foolproof. If a battery runs out or fails, the maglock will disengage, leaving your building unsecure. With motorized latch retraction, this is not an issue.

Free Egress

In many states, double redundancy is required for maglocks because they prohibit free egress. This often necessitates the installation of a Request to Exit (REX) switch in the device or touch bar, passive infrared sensor, or a Push to Exit button, adding to both costs and complexity. Failure to implement these can result in code violations. In contrast, motorized latch retraction systems inherently allow for free egress via the push pad, simplifying compliance with egress requirements and reducing installation costs.

No Misalignment or Aesthetic Issues

Motorized latch retraction systems can be integrated into existing door hardware, such as mortise or cylindrical locks, with minimal modification. This integration ensures precise alignment and functionality, eliminating common issues like misalignment or aesthetic discrepancies that can occur with surface-mounted maglocks. Additionally with no residual magnetism, there is no issue with “sticky” locks when using motorized latch retraction.

In addition to their functional advantages, motorized latch retraction systems operate quietly. Unlike maglocks, which can produce noticeable buzzing sounds during operation, motorized systems provide discreet security without causing disturbance.